"What is a state?": A question asked earlier this week in our first thermodynamics session. The first explanation was, "A state is not what you are in at 3am after a Saturday night out in Southampton".

This week we have started mechanics and thermodynamics, bringing our timetable up to 9am until 5pm everyday, except Friday where we finish at 4pm. Last week was much the same as the previous, but in workshop I was working on the male and female interlocking plates. First job was to get them into two perfect rectangles (think I've shown this in previous blog entries). Next up was working on the male part. Once this is finished I can begin the female and get it to fit the male. I'm almost there with the male and have got it very precise, leaving about 0.05mm extra metal to play with when fitting the female to it.

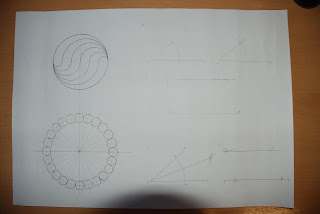

This week and last week I have been continuing my tangency exercises in Engineering Drawing. I've put all the photos below. I only have two more drawings to do before we move onto drawing a part we are given.

Below is an involute curve - definition is: A curved line that gradually becomes more distant from a centre point.

An involute curve can be traced by a point on a taut string as it

unwinds from a cylinder.

Anyway, now I'm caught up, back onto this week. Our mechanics teacher is a very young looking Korean man who assures us that despite his youthful looks, he is in fact 58. We were very surprised. He is very energetic and describes things in a very active way. For example, to demonstrate force he suddenly screwed up a piece of paper (to demonstrate how force deforms objects). Then he suddenly threw it into the wall to demonstrate a force making something accelerate. The first half an hour of his lesson was dedicated to him explaining the Korean alphabet, how he got his family name, and some more background history about him. A little off topic of course, but it's always interesting and a good beginning to know a little about who's teaching you. He also explained how he used to be a pretty keen shot when he was in the Korean Army for a few years (think they do/did national service), so he did a lot of shooting, the result being a seriously reduced frequency range for his ears. This means he cannot hear us at all if any background noise is sounding at the same time as we are. Currently, my only worry from our classes we've had so far is how well he'll be able to explain things to us - I say this as he begun at a very slow pace explaining simple things very clearly - we already understood these principles from maths. Then he suddenly accelerated massively and we were all left scratching our heads as to some of the things covered in the 5 seconds that had whizzed by. I'm sure once we've had a few more classes we'll know where we stand on that.

For the Thermodynamics we have our trusty Maths teacher, who explains things in a way we can all understand easily, so we're all glad about that.

In workshop our group have started Power Plant and have been told we will spend 72 hours doing this. Our instructor is brilliant and very generous with his time helping us to understand anything. In Power Plant we will study boilers, different types of pumps, engines, valves, generators, refrigeration, air conditioning etc etc. We will learn how they work, how to get into them to fix them safely (most importantly how to isolate them to work on safely), and how to move very heavy equipment around the workshop in order to do the former listed tasks. Today was mostly spent looking at what we will cover in the time. We also covered "Tag Out" systems - these are the systems companies use to identify what parts of a system have been taken out to safely repair it. Certain procedures are followed, including padlocks and labels added to parts to stop them being used and indicating which parts have been taken out. If properly followed this means you can't have somebody turning on a machine you are working on and killing you. What was stressed to us is that all companies have drastically different systems for this, so shortly after getting on board we need to understand how they run their system, so we can be safe. Aside from this we learned what is considered the one Engineering Malpractice - not knowing the consequences of what you are about to do to something. For example if you are about to use a tool in a way it wasn't designed for, then you better know what's the worst that could happen. IF you don't, then you could do something very stupid. The end of the session was dedicated to using the lifting gear to move a purifier (different types but some separate oil from dirt and water or fuel from dirt and water etc) across the workshop safely. Oh, and we also covered Permits to work. These are used by companies as a job brief when carrying out jobs at sea. They describe what the job is, how it will be safely performed, what systems it will involve (including what "Tag Outs" will be used. So we covered a bit about confined spaces in amongst this. Quite a few people die every year entering confined spaces so it's something the MCA are very hot on now, especially when it comes to the end oral exam, so you need to know you stuff.

What did amuse me today was that our instructor made a few mentions of touching wood during the session, and I did notice that he had a block of wood on the bench in front of him that he touched each time. I found out later the piece of wood actually had another use than just being there for safety. He also explained to us that although the majority of our workshop time would be spent welding, turning, milling, fitting etc, we would not be doing those at sea. What we cover in powerplant will actually be what we are doing day to day at sea. So it's rather unfortunate that only 72 hours are spent doing this, compared to about 300 hours of the other parts.